Pre-stressed Concrete

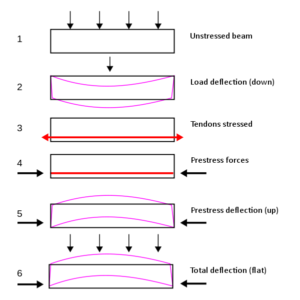

Fundamentals of concrete design says, concrete is weak in tension and strong in compression. Thus, to add tensile strength to the structure we introduce steel in concrete (Reinforced concrete structure). Sometimes amount of tension required to withstand the load is far more than strength of the structure. This happens due to various reasons like, on site limitation in size of structure and dynamic loading. To counter this issue, concept of pre-stressed concrete was implemented in many places like bridge, railway crossing. In layman term, in this method we introduce extra compression in tensile region of concrete before loading. So, after loading the load the structure, once developed tension was countered by the provided compression then only concrete will experience tension. This compression is introduced though tendons (High tension steel) with predefined tension in it.

This stress is created by tensioning a high strength steel “tendon” in or near concrete. The tendons commonly consist of a single wire, stranded wire, or threaded rod made of high-strength steel, carbon fiber, or aramid fiber. The essence of prestressed concrete is that once the initial compression has been applied, the resulting material has the characteristics of high-strength concrete when subject to any subsequent compression forces and of ductile high-strength steel when subject to tension forces. In a prestressed concrete member, the internal stresses are introduced in a planned manner so that the stresses resulting from the imposed loads are counteracted to the desired degree.

Image Source :- https://upload.wikimedia.org/wikipedia/commons/7/70/PrestressedConcrete-en1.png

Types of Pre-stressed concrete based on timing of tension introduction are:

- Pre-tensioning – Tensioning the tendons before casting through instruments like hydraulic jack. Major loss will be due to elastic deformation

- Post-tensioning – Tensioning the tendons after casting through instruments like hydraulic jack. Major loss will be due to friction and anchorage grip.

Downsides of Pre-stressed concrete

- Need careful attention for onsite casting

- Skillful workforce requirement

- Losses are enormous sometimes

- Requirement of higher grade of concrete

Increase in cost due to above requirements